top of page

GREEN MANTIS, LLC

SOFTWARE CAPABILITIES

Thermodynamic Calculations

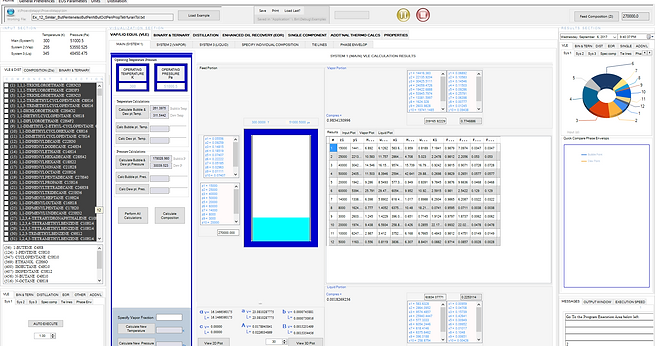

Our proprietary Software Package performs in-depth Vapor/Liquid Equilibrium (VLE) & Distillation Calculations for over 600 components. Systems can contain up to 100 components for all types of VLE analysis. The software package lets you compare the Boiling Point Temperatures and Pressures for up to 10 components from zero Kelvin to their critical points.

Used for Distillation column design over more expensive packages. Very portable, can be ran on any personal computer or tablet.

Currently being used to analyze and develop Operating parameters for Refinery units, Chemical and Polymer plants etc. Operating parameters include online or offline calculations for Temperature Controller setpoint curves for variations in Operating pressures. For systems with online analyzers, software package is used to calculate optimal temperature settings to achieve product specs. For systems without online analyzers, the package is used offline to generate operating setpoint curves for temperature controllers.

For Polymer plants, the software package is used to calculate Dew point temperatures to enable operating at the lowest optimal temperatures to maximize production and save energy.

The package has been used in conjunction with our Layered Advanced Process Controls solutions to solve the most challenging Process and Controls problems.

Let us utilize the capabilities of our software package, our knowledge of chemical engineering thermodynamics and experience with production facilities to solve your most challenging engineering, process and controls issues. We can re-design your process and help simulate the differences between the design and actual operations and then implement the controls/Advanced controls and optimization strategies using our software solutions to enable you to realize great savings and increased profits.

TRAINING

Engineering Training

We provide training using our proprietary software in the areas of Vapor/Liquid Equilibrium (VLE) and it's application in Distillation, EOR, Power Plants & Utilities, Chemical & Mechanical Thermodynamics and many other areas.

Our software provides a one-stop simulation shop for your process and controls needs.

Other areas of engineering training include:

-Controls and Advanced Controls

-Distributed Control System (DCS) Fundamentals.

- Refining, Petrochemicals & Natural Gas Fundamentals.

-Power Plant Fundamentals.

Operator Training

We provide Operator training in the basics of Chemistry, Physics and Mathematics as applicable to the Oil & Gas and Manufacturing industries.

Partnerships:

"AUGMENTED AND VIRTUAL REALITY APPLICATIONS

We are using Virtual Reality, Augmented Reality, and Interactive 3D to create memorable and transformative experiences across various industries."

bottom of page